Hammer Mills

Hammer Mills

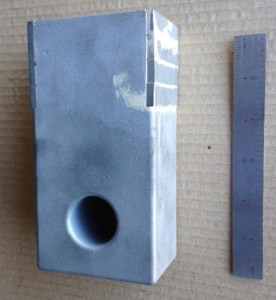

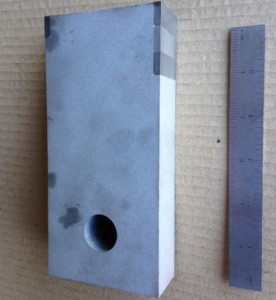

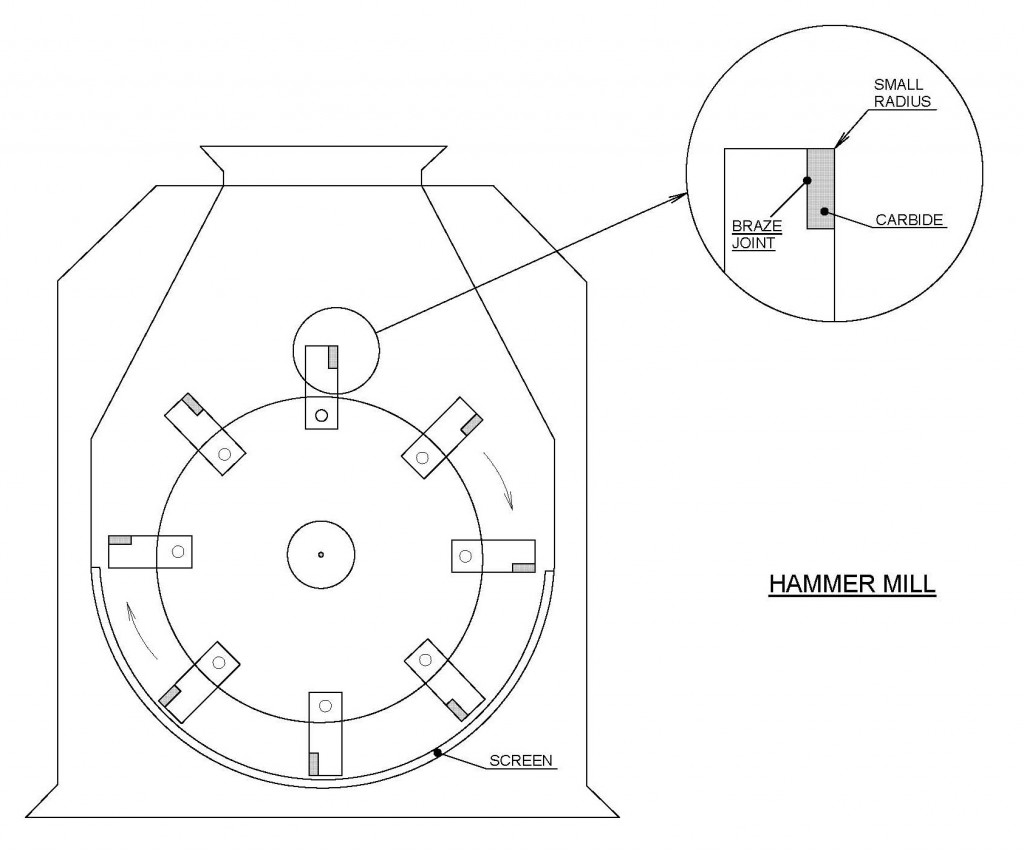

Swing-hammer tips take a beating. The abrasive nature of the raw material being pulverized, combined with the tip speed of the hammer, causes the cutting edge of the hammer to erode very quickly. Tungsten carbide works very well in this area. Universal Wearparts brazes in carefully selected impact-resistant grades of carbide.

The carbide-tipped hammer will maintain its original new part profile shape much longer than hammers with welded over-lays. With carbide hammers, you’ll decrease machine down-time and you’ll purchase fewer hammers over time. Universal’s carbide hammers are used to pulverize materials such as bark, coal, fiberglass, and shingles, and are used in recycling operations.

Universal’s carbide hammers are used to pulverize materials such as bark, coal, fiberglass, shingles, and are also used in recycling operations. Wood pellet producers can reduce downtime with carbide hammers in pre-dryer and post-dryer size operations. Carbide hammers can also be used to process feedstock for ethanol producers.